https://github.com/araobp/sensor-network

Wired sensor network for IoT with PIC16F1 MCU

https://github.com/araobp/sensor-network

daisy-chain i2c iot mplabx pic16f sensor-network

Last synced: 27 days ago

JSON representation

Wired sensor network for IoT with PIC16F1 MCU

- Host: GitHub

- URL: https://github.com/araobp/sensor-network

- Owner: araobp

- License: gpl-3.0

- Created: 2017-01-07T11:52:57.000Z (over 8 years ago)

- Default Branch: master

- Last Pushed: 2018-01-08T07:56:41.000Z (over 7 years ago)

- Last Synced: 2025-04-22T20:50:29.162Z (3 months ago)

- Topics: daisy-chain, i2c, iot, mplabx, pic16f, sensor-network

- Language: C

- Homepage:

- Size: 27.5 MB

- Stars: 8

- Watchers: 1

- Forks: 4

- Open Issues: 2

-

Metadata Files:

- Readme: README.md

- License: LICENSE

Awesome Lists containing this project

README

# Local wired sensor network

## Background and motivation

### Problems

I have developed a lot of IoT prototypes so far, then I have observed that most of my IoT projects require a communication protocol for wired sensor networking, satisfiying the requirements below:

- low power consumption and lower voltage (5V or 3.3V)

- bus topology (daisy-chain) rather than hub and spoke (star)

- two-wire or one-wire

- cheap (<$10 per node on average) and open

- small software footprint

There are a lot of such technologies for in-vehicle network (CAN/LIN), buidling management (BACnet) or factory automation (PROFINET), but none of them satisfies all the requirements above.

This is a project to develop a networking protocol and building blocks for local wired sensor network.

## Network architecture

The network is composed of multiple nodes(blocks) and one scheduler.

```

-----+---------------------+---------------------------+-------- I2C bus

| | |

+------|-----+ +------|-----+ +------|-----+

| [node] | | [node] | | [node] |

| | | | | | | | | ( )

| [sensor] | | [sensor] | | +------------[IoT GW(*1)]---( Cloud )

+------------+ +------------+ . . . +------------+ ( )

block block scheduler

(slave) (slave) (master)

(*1) I use Node-RED (on RasPi or PC) and Android as IoT gateways.

```

Note: I am going to support CAN bus as well.

### Interfaces among blocks

All the blocks developed in this project support [Plug&Play protocol](./doc/PROTOCOL.md) that runs on UART.

```

USB hub

+---+

[block A]--UART/USB--| |

[block B]--UART/USB--| |--USB--[IoT GW]

[block C]--UART/USB--| |

+---+

hub&spoke topology

```

It also runs on I2C.

```

<- - - - - I2C backplane - - - - ->

[block A]---[block B]---[block C]---[Scheduler]--UART/USB--[IoT GW]

bus topology (daisy-chain)

```

### 8bit MCU as core of node

I use [PIC16F1829/PIC16F1825](http://ww1.microchip.com/downloads/en/DeviceDoc/41440A.pdf) that satisfies the requirements of this project.

Clock speed:

- 4MHz typical

- 32MHz (8MHz w/ PLL) for high sampling rate

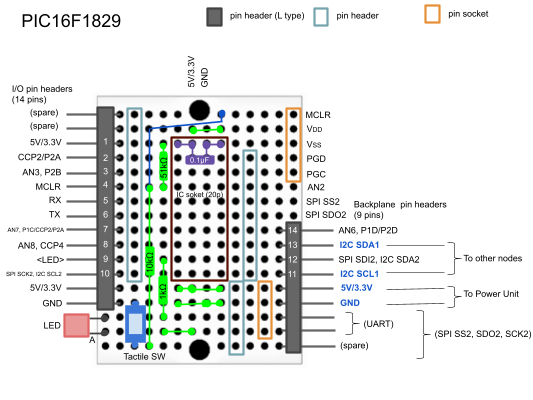

### Node prototype

The base board below is a common hardware part of node:

## Networking examples

One I2C master and three I2C slaves are connected with each other via backplane bus on the back of base board

A similar construct to the above, but all the boards are connected with each other in a daisy-chain manner:

## Implementation

I use Microchip's MPLAB-X IDE. I also use [MPLAB Code Configurator (MCC)](http://www.microchip.com/mplab/mplab-code-configurator) to automatically generate code for EUSART, I2C(master/slave), ADC, Timer etc. I modify the generated I2C slave code to support Plug&Play protocol.

### Plug&Play protocol

[Plug&play protocol specification](./doc/PROTOCOL.md)

Some blocks operates in pubsub mode -- [how it works](./doc/PUBSUB.md).

#### Implementation: common part among all nodes

All nodes need to import this [protocol library](./blocks/pic16f1829/lib/protocol.X):

- [Step1: include the protocol library directory](./doc/mcc_eusart4.png)

- [Step2: include the protocol library in your project](./doc/mcc_eusart3.png)

#### Implementation: I2C-slave-specific part

I2C slaves also require I2C-slave-specific code -- I modified MCC-generated I2C slave code (i2c1.c) to support the protocol on I2C slave side. See this modifed code: [i2c1.c](./blocks/pic16f1829/i2c_slave_lcd.X/mcc_generated_files/i2c1.c).

#### Coding

The following is an example of main routine:

```

void main(void)

{

// Protocol initialization

PROTOCOL_Initialize(DEVICE_ID, NULL, NULL, NULL, inv_handler, 250);

// avoid using SYSTEM_Initialize() automatically generated by MCC,

// because I2C1_Initialize() must be last in the initialization order

PIN_MANAGER_Initialize();

OSCILLATOR_Initialize();

WDT_Initialize();

ADC_Initialize();

TMR0_Initialize();

EUSART_Initialize();

I2C1_Initialize();

// Enable interrupt

INTERRUPT_GlobalInterruptEnable();

INTERRUPT_PeripheralInterruptEnable();

// Infinite loop

PROTOCOL_Loop();

}

```

### Blocks

#### PIC16F1829

In this project, PIC16F1829 MCU is used for general-purpose blocks such as a scheduler or LCD controller.

- [5V: Scheduler (BACKPLANE-MASTER)](./blocks/pic16f1829/i2c_master.X)

- [5V: Character LCD actuator block (AQM1602XA-RN-GBW)](./blocks/pic16f1829/i2c_slave_lcd.X)

- [5V: Acceleration sensor block (KXR94-2050)](./blocks/pic16f1829/i2c_slave_accel.X)

- [5V: Speed sensor block (A1324LUA-T)](./blocks/pic16f1829/i2c_slave_speed.X)

- [5V: Temperature and humidity sensor block (HDC1000)](./blocks/pic16f1829/i2c_slave_temp.X)

- [5V: Position detector block](./blocks/pic16f1829/i2c_slave_position.X)

#### PIC16F1825

In this project, PIC16F1825 MCU is used for purpose-specific blocks such as a position detector having multiple analog ports.

- [5V: Position detector block](./blocks/pic16f1825/i2c_slave_position.X)

A typical usage of the position detector is to detect a position of a moving object such as a doll on a catwalk miniature (not a belt conveyer).

Example of its usage

```

#WHO

$:WHO:MULTI_A1324LUA_T

#MAP

$:MAP:21,22

#RSC

$:RSC:0,0,0,0|0,0,0,0|0,0,0,0|0,0,0,0|0,0,0,0|0,0,0,0|0,0,0,0

#POS:0

#WSC:21

#POS:1

#WSC:22

#RSC

$:RSC:21,22,0,0|0,0,0,0|0,0,0,0|0,0,0,0|0,0,0,0|0,0,0,0|0,0,0,0

#I2C:21

#WHO

$:WHO:21

#SET:15

#I2C:22

#SET:9

#I2C:1

#STA

%21:UINT8_T:0,1,0,0

%21:UINT8_T:0,0,0,0

%21:UINT8_T:0,0,0,1

%21:UINT8_T:0,0,0,0

%21:UINT8_T:0,0,0,1

%21:UINT8_T:0,0,0,0

%21:UINT8_T:0,1,0,0

%21:UINT8_T:0,0,0,0

%21:UINT8_T:1,0,0,0

%21:UINT8_T:0,0,0,0

%21:UINT8_T:0,1,0,0

%21:UINT8_T:0,0,0,0

%21:UINT8_T:0,0,0,1

%21:UINT8_T:0,0,0,0

%21:UINT8_T:0,0,1,0

%21:UINT8_T:0,0,0,0

%22:UINT8_T:0,0,0,1

%22:UINT8_T:0,0,0,0

%22:UINT8_T:1,0,0,0

%22:UINT8_T:0,0,0,0

```

#### Initial config

Write I2C slave address on the blocks. For exmaple, if the address is 16 in decimal, then:

```

#WDA:16

#RDA

$:RDA:16

```

### CLI example

```

#WHO

$:WHO:BACKPLANE-MASTER

#SCN

#MAP

$:MAP:16,17,19

$:RSC:0,0,0,0|0,0,0,0|0,0,0,0|0,0,0,0|0,0,0,0|17,0,0,0|0,0,0,0

#POS:12

#WSC:19

#RSC

$:RSC:0,0,0,0|0,0,0,0|0,0,0,0|19,0,0,0|0,0,0,0|17,0,0,0|0,0,0,0

#STA

%17:UINT16_T:0

%19:FLOAT:-0.07,-0.08,0.94

%19:FLOAT:-0.05,-0.06,0.94

%19:FLOAT:-0.07,-0.06,0.94

%19:FLOAT:-0.06,-0.07,0.93

%19:FLOAT:-0.07,-0.08,0.94

%19:FLOAT:-0.05,-0.09,0.94

%19:FLOAT:-0.06,-0.09,0.94

%19:FLOAT:-0.05,-0.08,0.93

%19:FLOAT:-0.07,-0.08,0.93

%19:FLOAT:-0.06,-0.07,0.94

%19:FLOAT:-0.07,-0.07,0.94

%19:FLOAT:-0.06,-0.07,0.93

%19:FLOAT:-0.07,-0.08,0.93

:

#I2C:16

$:WHO:16

#CLR

#LED:ON

#LED:OFF

#STR:Hello World!

#NWL

#STR:Guten Tag!

#I2C:1

:

#STP

*:STP:ACK

```

### Interface to the scheduler

Use the CLI to control the scheduler or stream sensor data to the cloud.

#### via VCP over ttyUSBX(Linux)/COM port(Windows)

- Python: [pySerial](https://pythonhosted.org/pyserial/)

- Node.js: [serialport](https://www.npmjs.com/package/serialport)

#### via D2XX driver

- Java/Android: [D2XX driver](http://www.ftdichip.com/Android.htm)

### Physical wiring among blocks

In some projects, I used telephone line (6P4C) with RJ11 moduler plug/jack, as I2C bus. I used this tool to make wires among nodes: [Crimper for RJ11](http://www.mco.co.jp/products/tel/telephonetool/ta-642t.html). Telephone line makes physical wirling very easy.

6P4C telephone line is suitable for I2C with power line: SDA, SCL, 5V, GND.