https://github.com/danielmartensson/stm32-plc

STM32 microcontroller with lots of periferials such as ADC, differential ADC, Input Capture, PWM, USB, Encoder, DAC, Digital Input, RTC, CAN-bus + Alarm etc.

https://github.com/danielmartensson/stm32-plc

c can-bus embedded-systems stm32 usb

Last synced: 8 months ago

JSON representation

STM32 microcontroller with lots of periferials such as ADC, differential ADC, Input Capture, PWM, USB, Encoder, DAC, Digital Input, RTC, CAN-bus + Alarm etc.

- Host: GitHub

- URL: https://github.com/danielmartensson/stm32-plc

- Owner: DanielMartensson

- License: mit

- Created: 2021-08-18T14:25:17.000Z (over 4 years ago)

- Default Branch: main

- Last Pushed: 2024-02-09T12:38:10.000Z (almost 2 years ago)

- Last Synced: 2024-02-09T13:56:45.287Z (almost 2 years ago)

- Topics: c, can-bus, embedded-systems, stm32, usb

- Language: C

- Homepage:

- Size: 59.5 MB

- Stars: 70

- Watchers: 4

- Forks: 30

- Open Issues: 0

-

Metadata Files:

- Readme: README.md

- License: LICENSE

Awesome Lists containing this project

README

# STM32 PLC

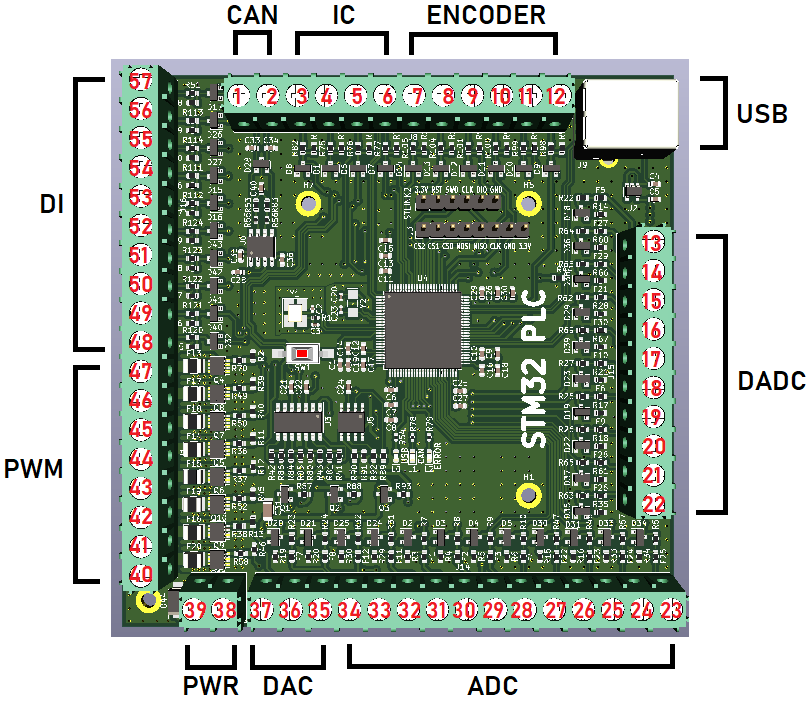

This project is a PCB bord that has the following measurement and control input/output:

* 12 x ADC at 16-bit resolution for 0-20mA input with programmable gain

* 5 x Differential ADC at 16-bit for 0-20mA input with programmable gain

* 3 x DAC at 12-bit with 0-20mA output

* 8 x PWM for 0-2.2A with N-channel MOSFET

* 10 x Digital Input

* 1 x CAN-bus channel

* 4 x Input Capture for 0 kHz to 10kHz

* 3 x Encoder for -32768 to 32767 pulses

* 1 x USB port for connecting with [OpenSourceLogger](https://github.com/DanielMartensson/OpenSourceLogger) and [GoobySoft](https://github.com/DanielMartensson/GoobySoft)

* 1 x SPI with 3 chip select for ILI9341 LCD with touch

* 1 x ST-Link V2 connection

* 1 x RTC clock with two alarms A(date) and B(week day) and a battery holder so the RTC remembers the date and time

## Protection

* All ADC, Digital Input, Differential ADC, Input Capture and Encoder are high voltage protected with PTC(fall current 30mA) fuse + 3.6v zener diode.

* All PWM and DAC are high voltage protected with N-channel MOSFET and PNP-transistor and OP-amp.

* The CAN-bus channel is high voltage peak protected for 3000V under a short time with a TVS-diode. The CAN-bus transmitter itself can hold against -14V to +14V, but the TVS-diode has a limit around 6V.

## Documentation

The documentation for the pin map can be found in the `Documentation` folder. Also all the article numbers for each component can be found in at the `DAC ADC PWM IO.sch` file in the `PCB` folder. Just double click on a PCB symbol and see the `Mouser Electronics` article number of the electrical component.

## Calibration

Yes, it's possible to set the calibration to each input in this project. You need to have the ILI9341 touch LCD with SPI bus. Open the `STM32 PLC Pinouts.pdf` and see the connection for the LCD. You can also set the PWM frequency and analog input gain for the ADC and Differential ADC at 16-bit.

## SAE J1939

The STM32 PLC has internal SAE J1939 protocol. Made from [Open-SAE-J1939](https://github.com/DanielMartensson/Open-SAE-J1939) repository.

## OpenSourceLogger

This is a QT C++ software that you can connect to your STM32 PLC board via the USB and then you can send signals from OpenSourceLogger and recieve signals.

OpenSourceLogger is a very easy to use logging and controlling software and it stores data at a SQL server.

## GoobySoft

This is a ImGui C++ project that do the same as OpenSourceLogger, but it's much better and have more features. The reason why I moved away from QT C++ to ImGui C++ is because

it's much easier to write a GUI application in C++ by using ImGui instead of QT. With QT, you are stuck with object oriented programming. Everything is a class.

But for ImGui, you can choose which type of lever you want to code, I prefer C-style C++ code with a small dose of object oriented programming (if needed).

Consider that I will work on GoobySoft instead of OpenSourceLogger.

## Program

The STM32 PLC has a lot of functions you can select by touching the LCD.

* A:Show measurement and time

* B:Set analog gain

* C:Set PWM frequencies

* D:Set analog input calibration

* E:Set pulses per encoder revolution

* F:Set date and time and alarm

* G:Do a PGN request

* H:Show ECU addresses

* I:Commanded address

* J:Show this ECU DM1 codes

* K:Show other ECU DM1 codes

* L:Show this ECU DM2 codes

* M:Show other ECU DM2 codes

* N:Show this ECU name

* O:Show other ECU name

* P:Show this ECU identifications

* Q:Show other ECU identifications

* R:SAE J1939 Auxiliary valve command

* S:Analog in to PWM

* T:Analog in to analog out

* U:About STM32 PLC

## How to build this STM32 PLC

1. Download this repository

2. Download & Install KiCad

3. Open the `PCB` folder and open the `.pro` file with KiCAD and greate a `gerber` file of your own choice

4. Go to your PCB manufacturer and give them the `gerber` file and let them produce the board for you

5. Order the eletrical components from `Mouser Electronics`

6. Once you have the eletrical components and your PCB board, it's time to solder them.

7. Once the PCB board is finished, then install STM32CubeIDE

8. Open the `Code` project and import the `.ioc` project file using STM32CubeIDE

9. Flash the board with the `C` code by using ST-Link V2 connection

10. Connect the ILI9431 touch LCD and then you are done!

## Software used

* KiCAD: 6.0.7

* STM32CubeIDE 1.10.1

## Status of the project

It's done. I don't plan to update this project. Everything is working and it will remain that way.